Cabin Enclosure Filter Pressurizers

Rethink Your Cabin’s Air Quality

Working in construction or mining sites often involves exposure to dust, debris, and harmful elements. It’s a common misconception that an enclosed cabin offers complete protection.

Harmful substances like VOCs (Volatile Organic Compounds) and SVOCs (Semi-Volatile Organic Compounds) can still infiltrate these spaces. Studies by global OH&S regulators reveal that the air inside a cabin can sometimes be more harmful than the air outside.

Miners are in danger due to extended coal dust exposure.

Many health issues arise from inhaling microparticles in the air.

- Inflammation of the lungs

- Fibrosis

- Black lung disease, also known as pneumoconiosis

- Necrosis

However, miners are not the only ones at risk. Workers in various industries, especially construction, are exposed to air contaminants that can lead to ailments ranging from asthma to silicosis. The intensity and duration of exposure directly correlate with the severity of health issues. For instance, exposure to diesel particulate matter, as studied by the Cancer Council Australia, shows a 40% increased risk of lung cancer among those exposed compared to the general population.

How can you help keep your employees and yourself safe in the workplace environment?

The answer lies in using cabin enclosure filter pressurizers. These systems are designed to filter out airborne toxins, significantly reducing the risk of inhaling harmful particles. While commonly used in mining equipment, these systems benefit industries facing similar air quality challenges.

How Do Cabin Enclosure Filter Pressurizers Work?

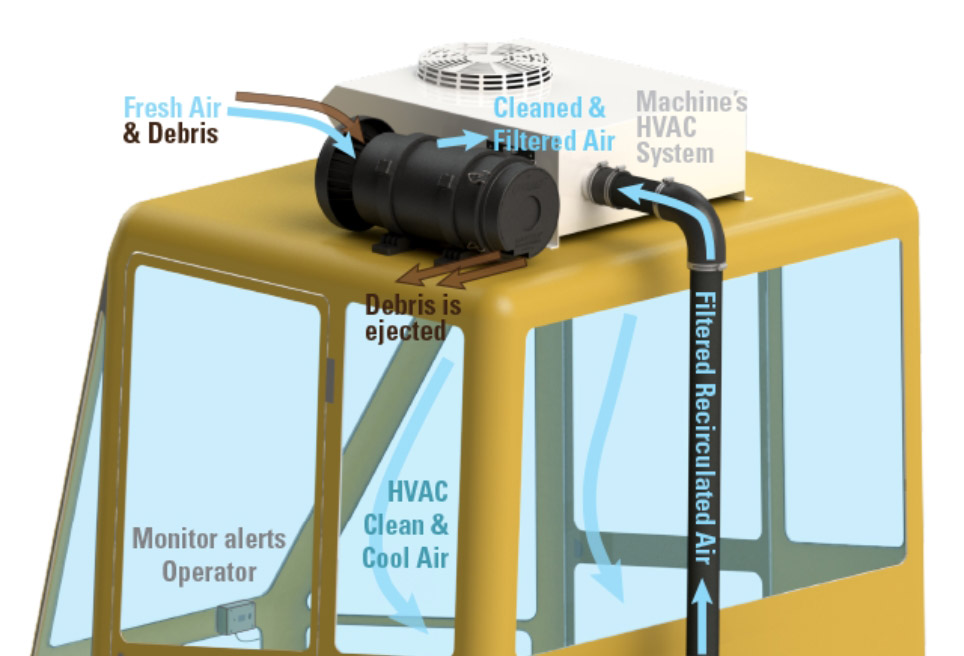

Here’s a simplified breakdown of their operation

1. Air Intake and Pre-Cleaning:

External air is drawn into the system, where large dirt particles are separated and ejected.

2. Dual Filtration:

Air passes through high-efficiency filters (EPA or HEPA), removing fine particles and ensuring only clean air enters the cabin.

3. Positive Air Pressure Creation:

The system delivers clean, filtered air to the cabin, maintaining positive pressure to prevent contaminants from seeping in through doors or windows.

Why Sy-Klone RESPA® Stands Out

Sy-Klone RESPA® systems are more than just air filtration tools—they are designed to meet and exceed industry standards.

Compliant with ISO 23875 and OSHA silica regulations, these systems address key concerns like settled dust removal, effective filtration, and continuous monitoring of cabin air quality. The RESPA Advisor+ further enhances safety by alerting operators to pressure loss or the need for filter replacement, ensuring consistent performance.

Beyond health protection, these innovative systems offer practical benefits. They significantly extend filter life, reduce maintenance costs, and enhance operator comfort. By maintaining cleaner cabin environments, RESPA® systems also protect sensitive equipment and electronics from environmental contamination, ensuring a more productive and cost-effective operation.

Adaptable Across Industries

Sy-Klone RESPA® systems are designed for versatility

Whether you’re working in mining, forestry, agriculture, waste management, or construction, these systems can be seamlessly integrated into various equipment, from operator cabs and control rooms to trailers and electrical cabinets.

An Effective Workplace Safety Solution

Cabin enclosure filter pressurizers offer a powerful solution to safeguard workers and enhance air quality in enclosed spaces. Among the most advanced options is the Sy-Klone RESPA® system, designed to revolutionize cabin air safety. These systems do more than just filter air; they actively maintain positive pressure inside the cabin, keeping harmful contaminants from seeping through doors, windows, and unsealed areas.

The process begins with external air being drawn into the system, where large debris is removed through pre-cleaning. This air then passes through highly efficient filters, including options like EPA or HEPA, which ensure that only clean air circulates within the cabin. By creating positive air pressure, the system purifies and prevents dirt and dust from entering, providing a continuous flow of fresh, safe air.

Take Action for a Safer Workplace

Contact Polar Mobility today to equip your cabins with our advanced filter pressurizers. Ensure a safer, healthier workplace and protect your equipment efficiently. Look at our comprehensive catalogue to learn more about our cabin enclosure filter pressurizers and take a step towards a cleaner, safer working environment.

Can’t find it? We’ll manufacture it to your specific needs. Contact us today!

Frequently Asked Questions

A cabin enclosure filter pressurizer ensures the air inside a vehicle cab is clean and free of harmful particulates. It creates positive air pressure within the cab, preventing dust, harmful gases, and other contaminants from entering, which is crucial for operator health and safety, especially in industries like mining.

The Sy-Klone RESPA system uses a high-efficiency particulate air (HEPA) filter and a pressurization unit to remove contaminants before entering the cab. The system ensures continuous clean airflow and maintains positive pressure to block dust and other pollutants from infiltrating the cabin.

RESPA systems provide clean air to operators, reducing their exposure to harmful particles like silica dust and diesel exhaust. This protects workers’ health and improves productivity by reducing fatigue and ensuring better air quality inside the cab.

Sy-Klone RESPA systems can be installed on various heavy-duty equipment such as haul trucks, bulldozers, excavators, and wheel loaders, making them ideal for mining, construction, and agriculture applications where air quality is a concern.

The Sy-Klone RESPA system is designed to meet or exceed air quality standards, including Occupational Safety and Health Administration (OSHA) regulations. Its filtration efficiency, including HEPA options, helps to ensure that the air inside the cabin meets required safety levels, protecting operators from airborne contaminants.

Regular inspections and maintenance are important for optimal performance. Depending on the operating environment, the filters should be checked and replaced as needed. Sy-Klone provides detailed guidelines for filter change intervals based on dust levels and other factors.

Yes, Sy-Klone RESPA systems are designed to be versatile. They can be retrofitted onto most types of heavy-duty vehicles and equipment, allowing you to enhance air quality protection without replacing your existing fleet.

Sy-Klone’s RESPA systems use patented precleaner technology and HEPA filtration to deliver superior air quality inside cabins. The systems are designed for heavy-duty environments, protecting against a wide range of contaminants while reducing frequent filter changes and maintenance costs.

By providing clean, filtered air and maintaining positive cabin pressure, RESPA systems reduce operator fatigue and discomfort caused by exposure to dust and pollutants. This improves focus, health, and overall productivity in challenging work environments like mining and construction.