Specialized Industrial HVAC Systems for Heavy-Duty Industries

At Polar Mobility, your comfort and safety are our top priorities. When you’re working long hours in construction, mining, or other heavy-duty industries—especially on those hot summer days—reliable climate control isn’t a luxury—it’s essential. Without proper air conditioning, you could face serious risks like heat stroke and dehydration, leading to OH&S issues.

Our mobile equipment air conditioning HVAC units are built to perform in even the harshest environments. Whether you need heating, cooling, or a combination of both, we deliver durable, low-maintenance solutions to keep your equipment—and your team—running smoothly. With options that include digital controls and stainless-steel construction, our systems are engineered for longevity and reliability.

When temperatures climb to 50°C or more, you need a high-capacity solution that won’t quit. Polar Mobility delivers powerful, purpose-built mobile HVAC systems that reduce operator fatigue, improve productivity, and ensure comfort—no matter how extreme the conditions.

Mobile Equipment Air Conditioning & HVAC: Units & Systems

Whether you’re working in the mining, construction, or other heavy-duty industries, our robust and reliable mobile equipment air conditioning and HVAC systems ensure that your equipment runs efficiently and your operators remain comfortable in even the harshest environments.

12-24 VDC Drive Systems

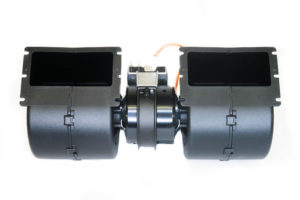

Our 12-24 VDC drive systems are designed to provide reliable cooling in various mobile applications. These systems are ideal for vehicles and equipment operating in demanding conditions, offering durability and consistent performance.

These low-voltage electric motor systems can operate on 12 to 24 volts of direct current, and are commonly used in automotive, agricultural, and industrial vehicles. This system is ideal when space is limited and reliable operation is essential.

High Voltage Systems

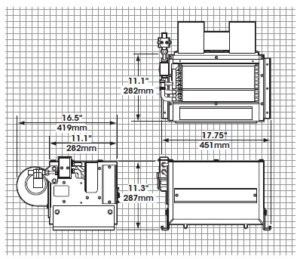

Our range of high-voltage mobile equipment air conditioning and HVAC systems delivers powerful cooling capabilities for equipment requiring high-voltage solutions. These systems are engineered to handle the increased electrical demands of larger, more complex machinery, ensuring they stay cool and efficient under load.

Engineered to thrive in the toughest environments, these durable, high-voltage units can withstand extreme temperatures up to 55°C, heavy shock and vibration, and even hazardous atmospheres.

Designed for versatility, our systems are compatible with both 2- and 3-phase AC power at 50/60 Hz, making them ideal for a range of applications. They deliver reliable, quiet, and energy-efficient heating and cooling while maintaining a clean, contaminant-free cabin environment. Every unit is built to maximize performance and operator safety, even under the most demanding conditions.

Available high voltage systems include:

- External wall-mounted heater air conditioners

- Modular ductable units

- Roofmount heater air conditioners

- Split systems

Hydraulic Systems

Our hydraulic AC systems are perfect for applications where hydraulic power is already used. These systems integrate seamlessly with existing hydraulic infrastructure, providing efficient cooling without additional power sources.

Hydraulic air conditioning systems function similarly to traditional automotive HVAC units but with one key difference: instead of relying on the engine to power the AC compressor, they use a hydraulic motor. These systems use an incompressible fluid—rather than gas—to transfer power efficiently through compact tubing and flexible hoses, making them ideal for delivering high power in demanding environments.

Widely used across industries such as construction, mining, transportation, and military operations, hydraulic AC systems are perfectly suited for heavy-duty equipment like shovels, haul trucks, dozers, loaders, drills, excavators, and underground machinery.

Our hydraulic systems include:

- Hydraulic compressor drives

- Remote condensers

- Rooftop modular units

Mobile A/C Units

Our mobile A/C units are specifically designed for the rigours of mobile environments. Focusing on durability and efficiency, our selection of solutions ensures that your operators stay cool and comfortable no matter where the job takes them.

Our mobile AC units are designed for maximum versatility and convenience, with easy-to-install kits that make setup simple—even in vehicles with limited space. We offer a wide selection of units from top industry brands, purpose-built for heavy-duty equipment, trucks, camper vans, buses, and more.

These compact yet powerful systems deliver reliable cooling to enhance comfort and safety for both drivers and passengers.

Our mobile units include:

- 12-24 VDC drive air conditioning

- Ceiling mount evaporators

- Non-electric hydraulic air conditioning

- Powered condensers

- Remote heater/evaporator

- Underdash evaporators

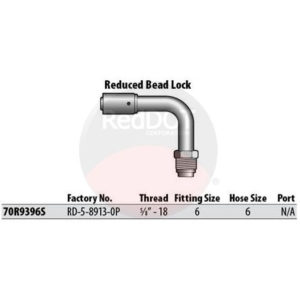

AC Parts

We offer a comprehensive range of AC parts to support your industrial HVAC systems’ repair and ongoing maintenance. Our inventory includes compressors, condensers, evaporators, hoses, and fittings, all selected for their quality and compatibility with heavy-duty equipment.

Why Choose Polar Mobility?

With our unmatched selection of industrial mobile equipment air conditioning and HVAC solutions, we’re committed to your comfort. Our products are built to withstand the demanding conditions of the mining, construction, and heavy-duty industries. From initial installation to ongoing maintenance, our team is here to support you every step of the way.

Contact us today for more information on our mobile equipment air conditioning and HVAC solutions or to request a quote. Let Polar Mobility be your partner in keeping your equipment cool and your operations running smoothly.

Frequently Asked Questions

Size of the Equipment: Appropriate sizing for mobile equipment air conditioning/HVAC units is crucial for effective operation. An undersized unit can fail unexpectedly during critical operations, leading to downtime, costly replacements, and potential loss of perishable goods.

Exposure to Elements: Mobile equipment air conditioning and HVAC systems must handle environmental hazards common in industries like mining and construction. This includes pollutants such as asbestos, toxic gases, chemical compounds, mould, dust, carbon monoxide, and nitrogen oxide, which can all severely impact worker health and equipment functionality.

Industry Regulations: Compliance with industry-specific regulations is essential. For example, transporting perishable goods like food and medical supplies requires adherence to specific codes. In heavy industries like construction and mining, systems must meet standards such as ISO 23875 to ensure clean air inside machinery cabs.

Heating and Cooling Split Systems: These are widely used systems that employ refrigerant, compressors, and coils for cooling, along with a furnace and a fan for heating.

Hybrid Split System: Hybrid systems are similar to split systems but offer the flexibility to switch between gas and electric power, enhancing energy efficiency.

Duct-Free (Mini-Split): These are wall-mounted indoor units connected to an outdoor compressor. They allow for individual climate control, which conserves energy by heating or cooling only occupied spaces.

Packaged Heating and Air: These compact units can be electricity or gas-powered and are designed for easy transport and versatility.

The cost of mobile equipment air conditioning and HVAC systems can vary based on vehicle size, cooling needs, chosen HVAC system type, and other specific requirements. Beyond the initial purchase price, consider the operational and maintenance costs. Consulting with HVAC experts like those from Polar Mobility can provide insights into the comparative costs of updating versus maintaining older systems.

HVAC technicians can perform various services, from repairing existing systems to installing new equipment. Regular service appointments typically include:

- System inspections

- Cleaning of components

- Adjustments of screws, belts, and other parts

- Refrigerant checks

- Fluid top-ups

- Fin straightening

- Fan function tests

- Thermostat calibration

- Ductwork inspection

- Filter changes

Regular maintenance extends the lifespan of mobile equipment air conditioning and HVAC systems, and helps identify potential issues early, preventing costly downtime and ensuring continuous operation.

Mobile Air-Conditioning/HVAC Units and Parts

Polar Mobility stocks and manufactures mobile AC/HVAC units and parts.

Can’t find it? We’ll manufacture it to your specific needs. Contact us today!

-300x225.jpg)

-300x300.jpg)

-300x300.jpg)

-300x300.jpg)