It’s important to protect your operators from exposure to harmful particulates. What is the solution?

You may work in the construction or agricultural industry and are concerned about the dust and airborne toxins in the environment. Do you also want to increase filter life and prevent costly maintenance downtime due to clogged machinery? You need to implement a pre-cleaning filtration system. Polar Mobility designs and manufactures air pre-cleaners for cabs and engines. Pre-cleaners come in powered and non-powered high-efficiency filtration. Both forms remove airborne dust and debris before reaching the main filter. Choosing a powered version will provide a more advanced form of filtration.

What does an engine air pre-cleaner do?

Are you looking for a solution to increase productivity and decrease operational costs?

An engine air pre-cleaner will do precisely this. Below is an example of why you need to install a pre-cleaning system in your machinery.

Agriculture industry workers go out daily to take care of their land and crops. Chaff from wheat grains gets stuck in the heavy farming machinery, causing the machinery to slow down and fail. This frustrates the operators. They have to stop what they are doing to clean out the system for it to work properly so they can continue their job. Having to clear the system causes a halt in production, wasting approximately 1-2 hours. By installing engine air pre-cleaners into the equipment, the main filter continues to operate at capacity, allowing the workers to continue production for about 3-4 days without touching the filter. Downtime is eliminated. Your costs are lower because you are paying your workers for production time, not wasted time. Fewer filtration issues translate into increased productivity, saving you money.

An added bonus of pre-filters is that changing the air filter less frequently is better because there is less chance of large debris passing into the engine. Your operators will feel more comfortable performing their jobs in a safer, cleaner environment. Worries about contamination in the air intake system are lessened with pre-filters.

How do engine air pre-cleaners work?

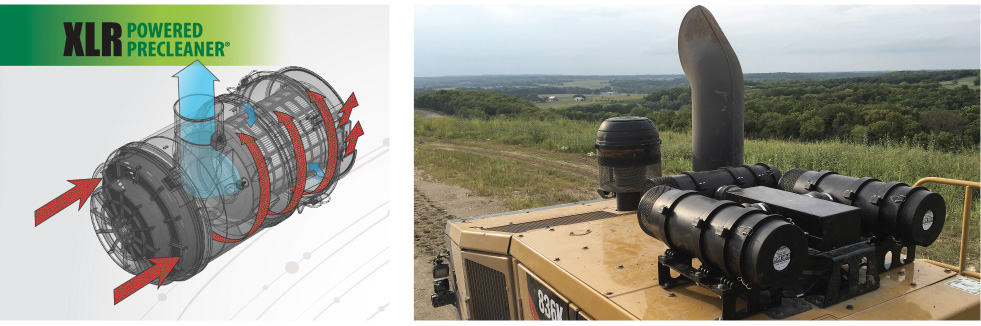

The pre-cleaner prevents particulates from penetrating your machine using finely punched mesh pre-screens. Removing any large debris from the air intake keeps the path clear. Next, the air streams down through fixed vanes, causing the air to spin and activate the rotor. The force from the spinning rotor is strong enough to push the contamination out of the air stream through discharging ports at the bottom of the unit. The clean air flowing into the air filter will now be 90% more pure.

Less debris entering your engine means less wear on cylinder surfaces, rings, and bearings. Air pre-cleaners save you money by preventing the need to purchase new machinery. Sy-Klone’s engine air pre-cleaners use finely punched mesh pre-screens to keep large debris out of the air intake. Incoming air is directed through fixed vanes, causing it to spin and activate a rotor. This spinning motion pushes contaminants out of the air stream and discharges them through ports at the bottom of the unit, leaving clean, filtered air to enter the engine—90% purer than unfiltered air.

Cleaner air flowing into your engine means less wear on critical components, like cylinder surfaces, rings, and bearings, which extends the life of your machinery. Investing in Polar Mobility’s Sy-Klone air pre-cleaners means extending the lifespan of your equipment, improving productivity, and reducing long-term costs.

Why choose Sy-Klone pre-cleaners?

Sy-Klone’s pre-cleaners are among the most effective in the industry, designed to remove up to 90% of airborne debris before it reaches the main filter. These pre-cleaners are available in powered and non-powered versions, providing tailored filtration for cabs and engines. With powered pre-cleaners, you benefit from an advanced level of filtration, capturing fine dust and debris that can compromise engine performance and operator safety.

Increase productivity, decrease downtime

Installing an engine air pre-cleaner can transform your equipment’s performance. Consider the agriculture industry: farmers face frustrating delays when dust and chaff clog their machinery, forcing them to stop work to clean filters. With a Sy-Klone pre-cleaner, these filters stay cleaner longer, allowing uninterrupted production for days at a time. Less downtime means your workforce is more productive, cutting operational costs and maximizing uptime.

The added value of pre-filters

Beyond reducing filter replacements, pre-filters also prevent large debris from entering and damaging the engine. By reducing the need for more frequent filter changes, pre-filters contribute to a safer, cleaner environment for your operators. Sy-Klone’s powerful pre-cleaning technology minimizes concerns about contamination, so your team can focus on the job without worrying about compromised air quality.

Take the first step toward cleaner air and longer-lasting equipment

Polar Mobility offers a range of Sy-Klone pre-cleaning filtration systems tailored to heavy-duty industries. Protect your workforce, boost productivity, and keep your equipment running at peak performance. Contact Polar Mobility today for products you can count on to help your equipment last longer and work better.

Frequently Asked Questions

An engine air precleaner is a device that removes large dust particles and debris from incoming air before it reaches the engine’s main air filter. This pre-cleaning process extends filter life, enhances engine performance, and is crucial for heavy-duty industries like mining, construction, and agriculture, where equipment often operates in harsh, dusty environments.

Sy-Klone air pre-cleaners use centrifugal force to expel dust and debris from the air intake system before it reaches the engine’s air filter. By significantly reducing the filter’s workload, Sy-Klone precleaners allow cleaner air to enter the engine, boosting combustion efficiency and engine health.

In mining, Sy-Klone precleaners help decrease equipment downtime, extend engine filter lifespan, improve fuel efficiency, and safeguard the engine against damage from excessive dust and debris. This robust filtration is critical in environments where equipment faces prolonged dust exposure.

Yes. By intercepting larger particles before they reach the main air filter, pre-cleaners reduce clogging and maintain a cleaner airflow for combustion. This results in better performance, fuel efficiency, and longer equipment life.

Sy-Klone precleaners are compatible with a wide range of heavy-duty machinery, including bulldozers, excavators, haul trucks, and other mining, construction, and agriculture vehicles. They are adaptable to various equipment types, ensuring reliable performance across multiple industries.

Unlike traditional air filters, which only capture dust and debris after they enter the system, Sy-Klone precleaners intercept up to 90% of contaminants before they reach the main filter. This reduces the need for constant filter replacements and maintenance, which is especially valuable in demanding, dust-filled work environments.

Sy-Klone air pre-cleaners are designed for low maintenance. Although periodic checks are recommended to ensure optimal operation, precleaners do not require frequent replacement. Regular inspection for any blockages or damage will keep them functioning at peak performance.

Yes, Sy-Klone precleaners can typically be retrofitted to a wide range of heavy-duty machinery. This allows operators to upgrade their equipment’s air filtration without needing a full system replacement, offering a cost-effective solution for enhanced air quality.

By filtering out dust and debris before it reaches the engine’s main filter, pre-cleaners reduce the frequency of filter changes, extend engine life, and cut down on equipment downtime. This directly translates to lower overall maintenance costs and increased operational efficiency in high-demand mining environments.

Engine Air Pre-Cleaner Units/Parts

Polar Mobility stocks and manufactures hundreds of engine air pre-cleaner units and parts to solve your air-quality problems.

Can’t find it? We’ll manufacture it to your specific needs. Contact us today!