ISO 23875 – Protecting Workers from Health Hazards and Improving Machine Efficiencies

A New Standard of Cab Air Quality

Polar Mobility offers solutions to ensure compliance with the new ISO 23875 standard for cab air quality, designed to reduce occupational exposure in operator enclosures.

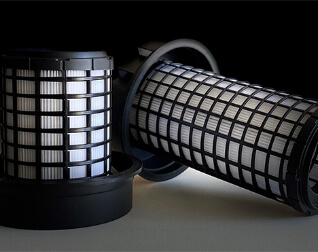

The standard mandates maintaining a minimum sustained pressure of 20 Pa and real-time monitoring of cab pressurization and CO2 levels. The Sy-Klone RESPA systems, including fresh and recirculated air systems, RadialSHIELD high-efficiency HEPA filters, and the RESPA Advisor+ monitor, provide the necessary designing controls to meet these stringent requirements.

Polar Mobility ensures new and existing equipment can be brought into compliance, enhancing operator safety and comfort while reducing exposure to harmful particulates.

XLR Powered Precleaner

RadialSHIELD HEPA filters

RESPA Advisor+ monitor

The Impact of ISO 23875

Heavy construction and mining workers are frequently exposed to harmful airborne particulates and high CO2 levels. Inhaling dust particles, exhaust fumes, asbestos, and silica can lead to severe long-term health issues.

When CO2 levels inside an operator cab exceed ambient CO2 + 400 parts per million (ppm), the air becomes unsafe, potentially causing impaired focus or even life-threatening asphyxiation.

Symptoms such as frequent sneezing and shortness of breath indicate exposure to contaminated air. Overexposure can increase the risk of developing medical conditions like asthma or heart problems.

ISO 23875 is an international standard implemented to ensure clean air within mining and heavy construction machine cabs. It establishes new requirements to limit liability from exposure to airborne particulates and CO2. Efficient cab design, regular testing, proper operation, and consistent equipment maintenance significantly improve the quality of breathable air.

Heavy equipment operator enclosures, whether new or already in use, must meet these performance standards to protect operators from environmental hazards that can lead to long-term health complications.

HVAC systems, which can easily become clogged with particulates, may fail or cease to function, recirculating contaminated air inside the cab and drawing in dust and CO2 from outside.

The new ISO 23875 international standard mandates that both new and retrofitted equipment comply with these needed regulations to protect the health and well-being of mobile mining and heavy construction operators. Implementing these standards not only protects workers but also reduces company liability.

New and Retrofit Design Standards

Design standards must meet stringent safety requirements to ensure structural integrity, reduce hazardous noise levels, and direct engine exhaust away from external air intake. Additionally, The design must provide operators with a clear field of view and proper access.

Performance Requirements

• The maximum CO2 level allowed is the ambient CO2 level plus 400 ppm.

• The maximum allowable respirable particulate matter concentration is less than 25 µg/m³ at the beginning and end of a decay test, with a maximum decay time of 120 seconds.

• Use ISO 15 E or ISO 35 H HEPA filters for improved HVAC filter efficiency and to minimize dust build-up and CO2 in the operator cab.

• Maintain a minimum sustained pressure of 20 Pa or higher (with the machine key in the “on” position) and ensure the maximum sustained pressure does not exceed 200 Pa.

• Any external devices must be simultaneously activated to provide proper air exchange when in operation.

• Visible and audible monitoring devices must meet ISO standards for pressure and CO2 under varying conditions.

Designing Requirements

• The operator enclosure must be completely sealed at all entry points to prevent particle infiltration.

• No modifications to protective structure systems are allowed without permission from the machine manufacturer.

• Materials used in the cab should be resistant to particulate accumulation.

• Areas of the cab prone to leakage should be oriented away from the external air intake system.

• Flexible connectors should be used to relieve vibration stress.

Testing requirements

Regular testing is mandatory to verify the minimum and maximum pressures within an operator enclosure. Real-time airborne particulate monitors are essential for detecting external leaks from filters, seals, intake areas, or damaged parts. CO2 tests must be conducted with an operator inside the cab or using a device simulating human CO2 generation. Decay tests should be performed without an operator to determine particulate concentration, and all results must be documented.

Equipment should be maintained at regular service intervals.

Implementing proper protocols and safety practices enhances operator awareness. Owners, managers, supervisors, and workers must familiarize themselves with the new ISO 23875 standard to reduce incidents of equipment failure, employee turnover, lung damage, and liability.

ISO 23875 Air Quality Standard Solutions from Polar Mobility

Polar Mobility stocks and manufactures hundreds of air-quality units and parts to solve your air-quality problems.

Can’t find it? We’ll manufacture it to your specific needs. Contact us today!