Direct vs Indirect Fired Heaters: What’s Right for Your Team?

Maintaining a comfortable temperature for employees is essential across industries such as manufacturing, healthcare, and construction. Heaters support employee well-being and are pivotal to maintaining proper conditions for stored products, drying concrete, and preventing equipment failures in cold weather.

If you’ve ever researched fuel-fired heaters, you’ve likely come across the terms direct-fired and indirect-fired. While these labels are common, they’re also widely misunderstood—particularly when details meant for air heaters are applied to coolant heaters used in trucks, heavy equipment, and off-road applications.

In this guide, we’ll cut through that confusion by first defining the true difference between direct vs. indirect-fired air heaters. We’ll then explain why all safe and effective fuel-fired coolant heaters operate on a clean, indirect principle.

Direct vs. Indirect-Fired Heaters: Key Differences

The terms direct-fired and indirect-fired mean very different things depending on what’s being heated:

- Air heaters, commonly used on construction sites or in temporary shelters, may be direct-fired or indirect-fired, depending on whether combustion exhaust mixes with the heated air.

- Coolant heaters, used in mobile equipment, operate on a completely different principle.

How Fuel-Fired Coolant Heaters Work

Fuel-fired coolant heaters use diesel or gasoline to generate heat that is transferred into an engine’s coolant system. That heated coolant then circulates through:

- The engine block, for cold-start protection

- Hydraulic systems

- Cab heaters

Critical to note, even when a coolant heater is described as direct-fired, the flame never touches the coolant. Instead:

- Fuel is burned inside a sealed combustion chamber

- Heat passes through the metal walls of a heat exchanger

- Coolant is warmed indirectly, without any contact with combustion gases

This sealed design enables clean operation, system safety, and a substantially reduced risk of contamination.

Direct-Fired Heaters Explained

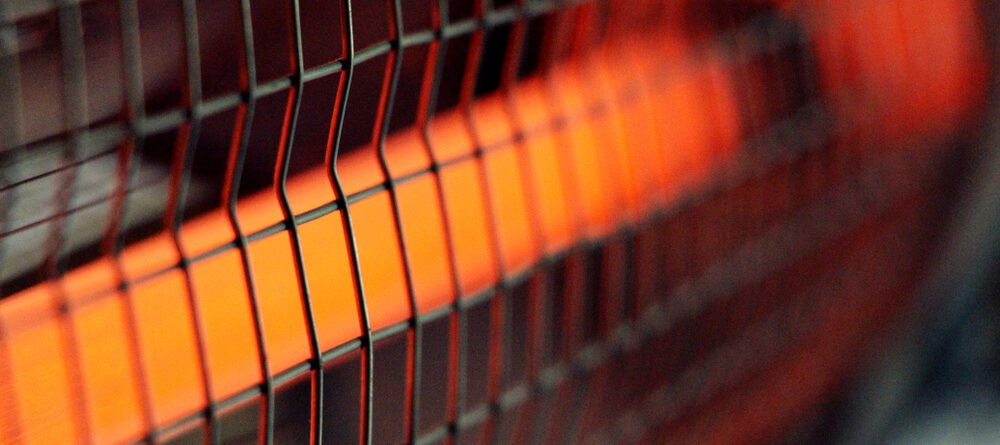

Direct-fired heaters utilize fuel (e.g., gas or oil) to heat air directly. An open flame inside the unit heats the incoming air, which is then expelled, providing rapid, substantial heat output.

Benefits of Direct-Fired Heating

- High Efficiency: Direct contact with the flame enables highly efficient fuel-to-heat conversion, making these units highly efficient.

- Cost-Effectiveness: The simplicity of their design reduces purchase and maintenance costs.

- Portability and Versatility: These heaters are designed to be movable and can efficiently heat large volumes of air.

- Low Operating Costs: They are more economical to run than electric heaters due to their high efficiency.

Limitations of Direct-Fired Heating

- Ventilation Requirement: The combustion process emits CO2 and moisture, requiring adequate ventilation in semi-open or well-ventilated large spaces.

- Not Suitable for Enclosed Spaces: The presence of people or animals in the heated area could pose health risks due to exhaust emissions.

- Risk with Flammable Materials: Their use near flammable or combustible materials is not advised.

Indirect-Fired Heaters Explained

Indirect-fired heaters encase the flame within a combustion chamber, separating it from the air stream via a heat exchanger. This design ensures that the heated air does not come into contact with the flame or combustion by-products.

Advantages of Indirect-Fired Heaters

- Clean Air Output: These systems expel pollutants through a chimney, delivering clean, hot air suitable for enclosed spaces without additional ventilation.

- Versatile Application: Ideal for indoor and outdoor use, these heaters can distribute warm air to multiple areas simultaneously.

- Safety and Comfort: The air is free from harmful fumes and odours, making it safe for use around people, animals, and sensitive materials.

Disadvantages of Indirect-Fired Heaters

- Lower Efficiency: Separating combustion products from the heated air stream slightly reduces efficiency compared to direct-fired heaters.

- Higher Costs: The complex design increases initial purchase and maintenance expenses.

Proheat & Espar Hydronic: Indirect by Design

Both Proheat and Espar Hydronic heaters are fuel-fired, indirect coolant heaters that use the same proven approach to coolant heating but differ in application.

Proheat X30

- Fuel Type: Diesel

- Heating Method: Burns fuel in a sealed combustion chamber and transfers heat through a heat exchanger

- Application: Engine pre-heat, hydraulic wing warming, cab heat support

- Category: Indirect fuel-fired coolant heater

Espar Hydronic Series (D5, M, L)

- Fuel Type: Diesel or gasoline (depending on the model)

- Heating Method: Identical sealed combustion and heat exchanger design

- Application: Engine and fluid warming access a wide range of mobile equipment

- Category: Indirect fuel-fired coolant heater

What Makes Indirect Coolant Heating Ideal for Canadian Winters?

In cold climates, especially across Canada, indirect fuel-fired coolant heaters offer clear advantages:

- Reliable cold starts even in extreme temperatures

- Reduced engine wear from dry or frozen starts

- Lower idle time, saving fuel and reducing emissions

- Consistent hydraulic performance in cold conditions

- Safe operation with no exhaust contamination

For fleets operating in remote locations or harsh environments, these benefits translate directly into reduced downtime and longer equipment life.

Choosing the Right Heater for Your Vehicles

When choosing the right heater for your operation, it’s important to consider:

- Your equipment size and engine displacement

- Operating environment and temperature extremes

- Runtime requirements

- Installation space and electrical capacity

If you’re comparing options and are unsure which heater best fits your equipment, reach out to one of our experts, and we’ll be happy to help!

Why Choose Polar Mobility

When you’re considering direct- vs. indirect-fired heaters, whichever you choose should be durable, reliable, and capable of withstanding the operating environment. At Polar Mobility, we offer high-quality indirect-fuel-fired heaters designed for equipment operating in demanding conditions. Our lineup includes:

- Proheat Dometic fuel‑fired heaters for robust, high‑output applications

- Hydronic heaters like the Espar D5-SC, ideal for compact installations and targeted heating needs

With proper heat transfer, you get clean, efficient, and safe heating to keep you productive all winter long.

If you’re planning for cold-weather conditions at your worksite or upgrading your current heating system, contact Polar Mobility for more information. We’ll be happy to help you find the right solution for your fleet.