Industrial HEPA Filters for Heavy Equipment, Mining and Transportation

n heavy-duty industries such as mining, construction, and transportation, air quality is critical for comfort and safety. Operators are often enclosed in cabins where fine dust, diesel fumes, and harmful airborne particles can accumulate quickly. If left unchecked, airborne contaminants pose serious health risks and can reduce the performance and longevity of expensive equipment.

Industrial HEPA filters offer a powerful solution. Engineered to capture even the smallest particulates, these filters are an essential component of effective HVAC systems in extreme working environments. This article explores how HEPA filtration works, its industrial advantages, and why it’s a must-have for heavy-duty operations.

What Is a HEPA Filter?

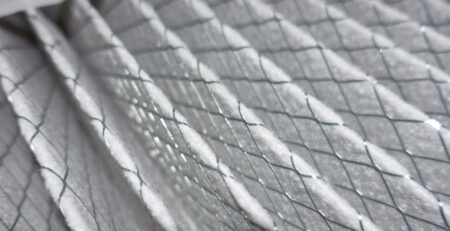

HEPA stands for High-Efficiency Particulate Air. HEPA filters are built to trap 99.97% of airborne particles measuring 0.3 microns in diameter, which is the most penetrating particle size (MPPS). Their multi-layered fibre design captures contaminants like:

- Fine silica dust

- Diesel particulate matter (DPM)

- Soot, allergens, and pollen

- Bacteria and airborne viruses

Unlike standard air filters, HEPA filters rely on diffusion, interception, and impaction to stop particles from passing through. This makes them especially effective in harsh industrial environments with constant ultra-fine dust and toxic fumes.

Why HEPA Filters Are Essential in Mining and Heavy Equipment

Protecting Worker Health

Operators working in mining and construction are exposed to silica dust, diesel exhaust, and bioaerosols, all of which are linked to chronic lung conditions like silicosis, COPD, and even cancer. Properly installed HEPA filters in cabin HVAC systems drastically reduce exposure, helping to keep workers safe and alert.

Preserving Equipment Performance

HEPA filters don’t just protect humans—they protect machines. Dust and particulate matter can clog HVAC units, sensors, and electrical components, leading to overheating, frequent maintenance, or equipment failure. By keeping these systems clean, HEPA filters:

- Extend equipment lifespan

- Improve engine and HVAC efficiency

- Reduce downtime caused by maintenance

Meeting Industry Standards

With growing attention to air quality in industrial sectors, HEPA filtration systems also help companies comply with ISO 23875, MSHA, and other safety standards. These regulations require specific levels of filtration and cabin pressurization to protect operators in high-exposure environments.

How HEPA Filters Work in Industrial Applications

HEPA filters rely on a multi-stage air filtration process to ensure operator cabins and engine compartments stay clean. Here’s how it works:

- Air enters the system through an intake duct or HVAC unit.

- A pre-filter captures larger particles like dust and debris.

- The HEPA filter then traps microscopic pollutants, including DPM and fine silica dust.

- Clean air is circulated back into the cabin or equipment enclosure.

Some systems also include activated carbon filters to remove gases, odours, and volatile organic compounds (VOCs), providing extra protection in enclosed, high-exposure environments.

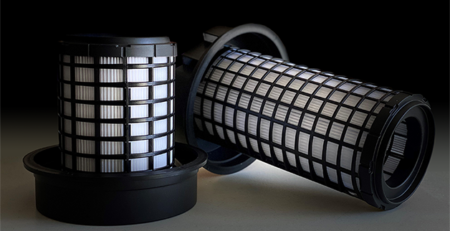

Choosing the Right HEPA Filter for Your Equipment

Not all HEPA filters are created equal. When outfitting your fleet or site equipment with industrial filtration, consider the following:

- MERV Rating: Look for filters rated MERV 16 or higher to ensure high-efficiency particle capture.

- System Compatibility: Ensure the filter fits your equipment’s HVAC or air intake system.

- Durability: Choose filters built to withstand vibration, moisture, and dust loading in rugged environments.

- Multi-Stage Design: Filters with pre-filters or activated carbon layers offer extended performance and improved protection.

Investing in quality filtration can reduce long-term maintenance costs and minimize health-related liability for your workforce.

Premium Air Quality Solutions from Polar Mobility

In industries where equipment operates under constant stress and workers are exposed to dangerous airborne contaminants, industrial HEPA filters are essential. Whether you’re managing a fleet of haul trucks in a remote mining operation or maintaining heavy equipment on a dusty construction site, HEPA filtration offers unmatched protection.

At Polar Mobility, we provide industrial-grade HVAC and filtration systems designed for the harshest conditions. From advanced Sy-Klone RESPA® filters to custom cabin pressurization units, our solutions help you stay compliant, productive, and protected. Don’t see what you need? Contact our team for our custom solutions.