The compressors & clutches of an air conditioning unit are needed for fully functioning capabilities.

The compressor is the heart of the air conditioner. Piston operated vapour pumps are driven by the electric motor of your HVAC unit.

What does the compressor do?

It takes the refrigerant gas and squeezes it so the temperature and pressure rise and exit the compressor as a hot, high-pressure gas. Compressors are available with electric or hydraulic drives. With dependable performance, you can rely on a solid compressor from Polar Mobility for all your heavy-duty requirements.

What is the operating function of the clutch?

The clutch spins a friction plate to use the motor’s power for turning the compressor on and off when needed. Need a new clutch or another part for your HVAC unit? Polar Mobility can order any part you need to keep your systems operating at full capacity.

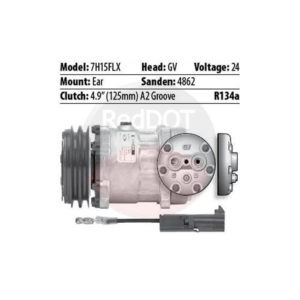

Polar Compressors and Clutches

If we made it, we service and supply for it!

Can’t find it? We’ll manufacture it to your specific needs. Contact us today!