Direct vs Indirect Fired Heaters: What’s Right for Your Team?

There are two types of fuel fired heaters: direct and indirect. The right fuel fired heater depends on a few factors.

This guide outlines the differences between direct-fired and indirect-fired heaters, detailing their benefits and drawbacks. This information will assist in identifying the most suitable heating system for your needs.

Maintaining a comfortable temperature for employees is essential across various industries, including manufacturing, healthcare, and construction. Heaters contribute to employee well-being and are pivotal in ensuring the right conditions for stored products, drying concrete, and preventing equipment failures in cold weather.

Selecting an effective heating solution that is both flexible and efficient can be challenging, especially considering the diverse needs of workspaces and site locations.

Both direct and indirect-fired heaters offer viable solutions, but the choice between them hinges on your needs.

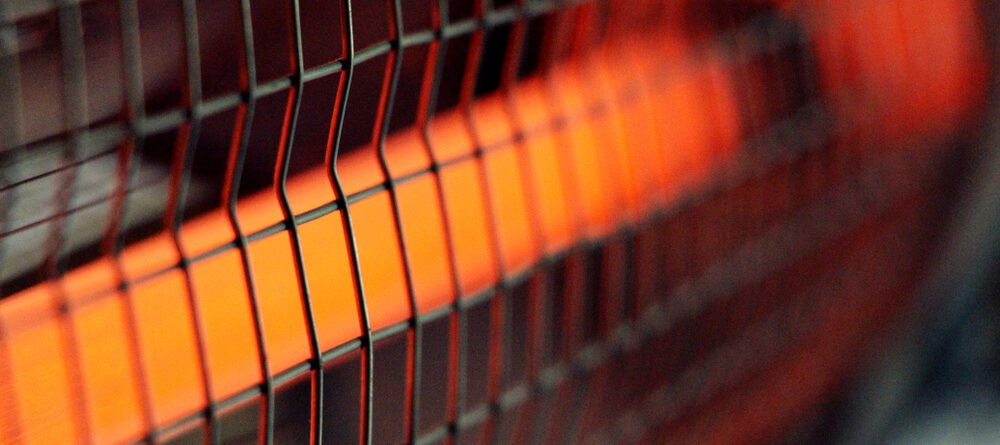

Direct-Fired Heaters Explained

Direct-fired heaters utilize fuel (e.g., gas or oil) to heat air directly. An open flame inside the unit heats the incoming air, which is expelled, offering rapid and substantial heat output.

Benefits of Direct-Fired Heating

- High Efficiency: Direct contact with the flame allows for nearly complete fuel-to-heat energy conversion, making these units highly efficient.

- Cost-Effectiveness: The simplicity of their design results in lower purchase and maintenance costs.

- Portability and Versatility: These heaters are designed to be movable and can efficiently heat large volumes of air.

- Low Operating Costs: They are more economical to run than electric heaters due to their high efficiency.

Limitations of Direct-Fired Heating

- Ventilation Requirement: The combustion process emits CO2 and humidity, necessitating good ventilation in semi-open or well-ventilated large spaces.

- Not Suitable for Enclosed Spaces: The presence of people or animals in the heated area could pose health risks due to exhaust emissions.

- Risk with Flammable Materials: Their use near flammable or combustible materials is not advised.

Indirect-Fired Heaters Explained

Indirect-fired heaters encase the flame within a combustion chamber, separating it from the air stream via a heat exchanger. This design ensures that the heated air does not come into contact with the flame or combustion by-products.

Advantages of Indirect-Fired Heaters

- Clean Air Output: These systems expel pollutants through a chimney, providing clean, hot air suitable for enclosed spaces without additional ventilation.

- Versatile Application: Ideal for indoor and outdoor use, these heaters can distribute warm air to multiple areas simultaneously.

- Safety and Comfort: The air is free from harmful fumes and odours, making it safe for use around people, animals, and sensitive materials.

Disadvantages of Indirect-Fired Heaters

- Lower Efficiency: Separating combustion products from the heated air stream results in slightly reduced efficiency compared to direct-fired heaters.

- Higher Costs: The complex design increases initial purchase and maintenance expenses.

Making the Right Choice

Choosing between direct and indirect-fired heaters depends on specific needs. Indirect heaters are preferable for environments requiring clean air, such as storage facilities sensitive to odours and temperatures. Direct heaters, offering high efficiency and low operational costs, are suited for applications like protecting water bottles from frost.

Examples of Application

Industrial Halls

A powerful direct-fired heater might be suitable for large factories where air exchange is sufficient to maintain air quality.

Temporary Accommodation

Smaller indirect-fired heaters ensure safe and comfortable conditions for heating refugee tents and similar spaces.

Construction Sites

Both heater types may be necessary at different stages, with indirect heaters preferred for enclosed spaces and direct heaters for outdoor or partially constructed areas.

Ultimately, safety and the specific heating requirements should guide the choice between direct and indirect-fired heaters.

Espar/Eberspacher Heaters

Espar heaters emerge as a reliable option for climate control across various commercial applications. Engineered to function independently of the engine, they reduce idling, save on operational costs, and minimize emissions. The Espar Airtronic, known for its high heat output and German engineering, provides comfort and safety across extreme temperatures, making it suitable for construction cabins, utility vehicles, boats, and more.

The Dometic Proheat X30

The Proheat X30 stands out with its 31000 BTU/hr heating capacity, offering efficient heating for heavy-duty applications. Its four operation modes cater to different needs, from pre-engine warm-up to preventing coolant freezing. This system reduces idling and ensures reliable heating performance, making it an ideal choice for keeping equipment and passengers comfortable.

Choosing the Best Fuel Fired Heaters for Your Team From Polar Mobility

Choosing between direct and indirect-fired heaters depends on your specific environmental and operational needs. With innovative solutions like Espar/Eberspacher Hydronic heaters and Proheat heating solutions, you can enjoy efficient, reliable heating while meeting industry demands and maintaining comfort. Polar Mobility remains at the forefront, offering state-of-the-art fuel fired heating products to suit various applications, ensuring your team stays warm and productive through the cold months.