What is the Role of an Engine Air Pre-Cleaner?

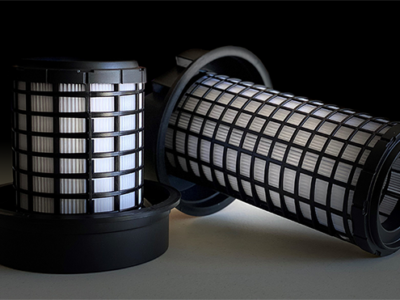

For extreme environments and heavy-duty industries, high levels of dust and debris are unavoidable. Mobile equipment operating under these conditions is especially vulnerable—engine components can quickly become clogged with contaminants, leading to reduced performance, premature failure, and costly repairs. While most engines have air filtration systems, excessive particulate matter can...