Mobile Heating Equipment: Fuel-Fired Heaters

When you need a self-contained and automatically controlled mobile equipment heating solution, a fuel-fired heater is a reliable option. You can find fuel-fired heaters in the manufacturing industry, for use in warehouses, the construction industry, and remote sites that need a stand-alone HVAC system. Espar/Eberspacher is a top brand for commercial and industrial use while Proheat is a top choice for military applications. a reliable and industry-leading name.

How does a fuel-fired heater work?

Fuel-fired heaters transfer heat through the combustion of fuel, effectively heating fluids contained inside coils.

Fuel-fired heaters are a solution for heavy-duty equipment to protect the engine from freezing and to maintain a comfortable temperature for operators in the cab and sleeper. They can operate when the engine is off, further protecting it from damage in extreme weather conditions and avoiding idling.

The 3 types of fuel-fired heaters include:

- Hydronic/Liquid Coolant – Coolant fluid is circulated and heated for remote heating.

- Diesel Fuel or Gasoline for Fuel Source – Uses fuel from the equipment as the energy source.

- Air Heaters – Circulates air instead of liquid for remote heating. The air must be void of combustion byproducts like carbon monoxide and carbon dioxide for safety.

The different types of fuel-fired heater units

The coils and the heating unit itself will differ in configuration depending on the application and the industry. At Polar Mobility, we work with clients that need a customized solution for their particular application.

Below are the different types of units to be familiar with:

- Gas Fired Duct Units – Designed to fit in ductwork for convenience with pre-wired or pre-piped assembly.

- Oil Fired Duct Units – Non-flammable process for heating a space and helps keep energy costs down.

- Direct Fired Heaters – A unit that involves the flame coming into direct contact with the air.

- Indirect Fired Heaters – The air passes over an enclosed heating element to warm the environment.

- Radiant Heaters – Heats objects rather than the air.

- Gas Fired Make-Up Air Units – Used for applications with frequent air changes and can adjust for both indoor and outdoor use.

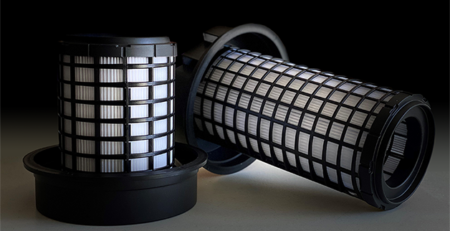

Fuel-Fired heater parts

Fuel-fired heaters involve a complex system of parts. Depending on the industry and use, other components can be attached to enhance the efficiency and safety of the unit, including:

- Waterproof Connectors – For protection against electric shock when using machinery in snowy and wet conditions.

- Exhaust Drains – This allows a small amount of gas to escape which extends the life of the exhaust system.

- Fuses – Prevents circuits from overloading.

- Testers and Adapters – Tests for pressure and intuitively adapts to changes. This is a key component for reducing the risk of system failures or dangerous explosions.

- Thermostats – Controls an exact temperature range and is a crucial part of all HVAC systems. Damaged thermostats must be serviced or replaced.

- Fuel Pick-Up Pipes – Moves heater fuel directly from the fuel tank.

- Switches – Allows operators to easily turn the heat on and switch it off. Damaged switches must be replaced.

- Timers – Allows the heater to automatically turn on and shut off with a pre-set time.

- Mufflers – Reduces noise from the exhaust system.

- Mounting Brackets – Provides strong support for mounting the unit anywhere on a wall, structural steel, pipe, or overhead structure.

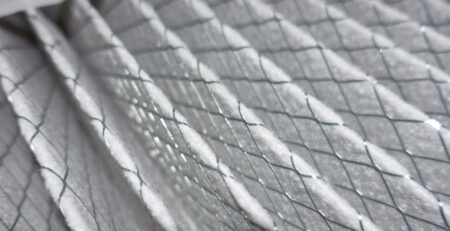

- Ducting Accessories – Different accessories for varying job sites to maintain flexibility in cold weather conditions.

- Plumbing Accessories – Simplifies plumbing and can be manufactured to a company’s specifications.

From the details above, you can see how many options you have for building the right mobile heating equipment for your operations. A good unit will not only effectively maintain a comfortable working temperature and protect equipment but will help keep your operational costs down by reducing downtime and lowering the risk of the unit breaking down.